Mechanical Tests

Unplanned down time for process and machinery is very expensive and may be prevented by implementing a thermal inspection procedure as many of our clients have implemented with our help.

Unplanned down time for process and machinery is very expensive and may be prevented by implementing a thermal inspection procedure as many of our clients have implemented with our help.

Worn bearings and mis-aligned pulleys can cause unexpected downtime usually at periods when it is least expected and highly unwelcome. We can predictively identify areas of potential problems and literally see it before it becomes a problem! Predictive maintenance demonstrated.

The sample images below indicate some potential failures

OUR Services

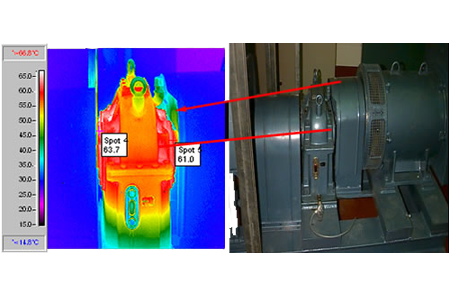

Motors and Gears

The temperature of the Gear Reducer indicated in the thermal image needed further inspection by the mechanical department

The temperature of the gearbox drive bearing was operating at a high temperature and needed to be overhauled

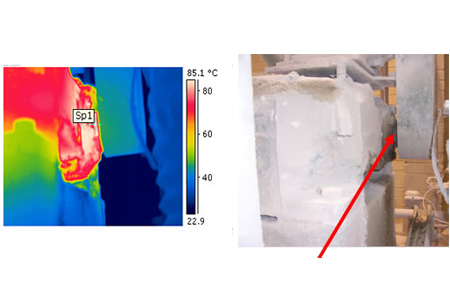

The bearing for the above fan needs to be replaced as soon as possible as the shaft is sliding on the bearing.